|

|

|

Page 5 |

Newsletter 113, Summer 2016 © Hampshire Mills Group |

Double

row of Alternating Cogs

Nigel

Harris

|

|

|

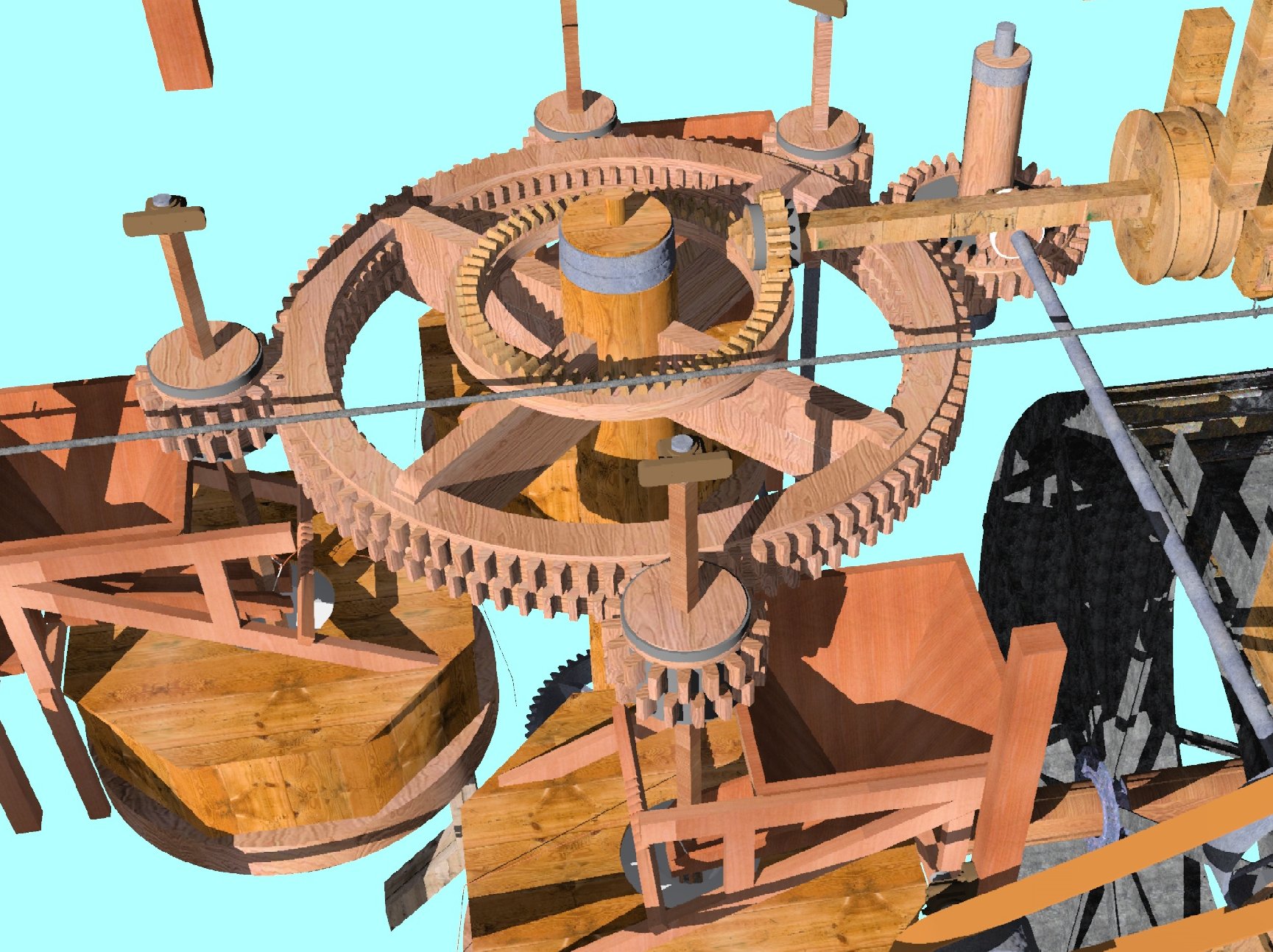

I wonder if HMG readers might be able

to help. I was browsing through John Brandrick’s

mill drawings on his website

(www.milldrawings.com)

and noticed that Rhydlydan Mill, Powys shows the

great spur wheel and some of the stone nuts, with

double rows of alternating cogs (left).

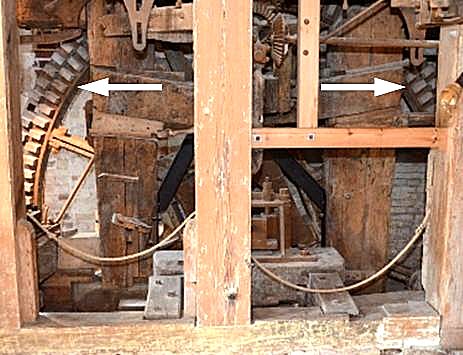

This arrangement is something I have

only come across once before and that was on the

very large pitwheel at Houghton Watermill,

Cambridgeshire (pictured below, left by Nigel

Harris, right by Ruth Andrews). |

|

John Bedington (ex Charlecote

Watermill) tells me that he has only once seen this

arrangement, on the brake wheel and wallower in the

windmill now at Madingley, Cambridgeshire (removed

from Ellington, Huntingdonshire). He also mentioned

that Rex Wailes, in “The English Windmill” seems to

treat this example as a one-off for windmills and

says ‘the brake wheel and wallower have two rows of

staggered cogs, evidently to avoid backlash’.

The double row of cogs would be

stronger than one row, but the point of staggering

the teeth would seem to be to reduce backlash in the

gears (that is, rattle, because of play between the

cogs). The double row would reduce noise and

possibly make the cogs less likely to break. It

would also have the same effect as having a finer

pitch of cog.

I suspect other examples may exist;

do let me know if you know of any.

nigel.harrismsc@gmail.com

|

|

|

Editor’s note:

Keith

says that twin staggered teeth are a feature of the

Abt system of rack railways. It is used on the

Snowdon Mountain Railway and the Gornergrat railway

at Zermatt (illustrated), for example. As well as

the advantages that you mention, it also means that

the gear wheel on the locomotive and the rack (and

in the case of the mill, the two gear wheels) are in

more constant mesh, and therefore will be safer

because they are less likely to jump out of

engagement. (This is possibly more important in a

rack railway than a mill.)

|

|

|

|