|

|

|

Page 8 |

Newsletter 114, Autumn 2016 © Hampshire Mills Group |

The

Arthur Lowe Photo Collection

Information

from Tony Yoward

|

|

Mr Lowe died on Sunday 18 August 1996 at the Gosport

Memorial Hospital aged 90 years. He was born on 2

April 1906.

He left his collection of maps

and photographs to the Hampshire Mills Group. The

photographs were put into archival hangers in seven

albums containing almost 1500 photographs, which

have now been deposited at The Mills Archive in

Reading.

A few of his earliest photos

are included below.

This article was

published in Yesterday in 1994.

Cycling into a Land full of Sails

|

|

On a cycle ride from his Gosport home in 1926,

Arthur Lowe espied the mill at Earnley, near

Chichester (pictured). The sails, two of canvas and

two shuttered, were turning in a brisk breeze and

seemed like arms beckoning him. He called on the

miller, a Mr Ellis, who showed him all over the mill

while flour was being ground. "The whole building

seemed alive with the creaking of wooden machinery

and the rumble of the stones, and it was quite

absorbing. From then on I was fascinated by mills,

wind and water, and they have been important to me

ever since" said Mr Lowe, of Braemar Road,

Bridgemary, Gosport. Since that day he has visited

many mills, later adding dovecotes to his interest,

and on his trusty bicycle has travelled all over

England to visit and photograph them.

His cycling mileage has topped 350,000, and the

tally of mills he has visited and photographed comes

to 600 watermills and more than 170 windmills. At

home he would pore over Ordnance Survey maps looking

out mills and planning his journeys. He covered

Hampshire. West Sussex, and adjoining counties, the

Isle of Wight was within easy reach, and he pushed

his boundaries further, Surrey, Kent, Essex,

Cambridgeshire, Lincolnshire. Weekends were full,

holidays were devoted to the further flung counties.

On the iron rail to Woking, then into the saddle,

and before long the eastern counties sped beneath

his questing handlebars. Now on his third bicycle

and third camera, Arthur still spends many happy

hours cycling to his beloved mills, often taking his

bike on a train in order to reach the far off ones,

having given up his car in 1958.

|

.jpg) |

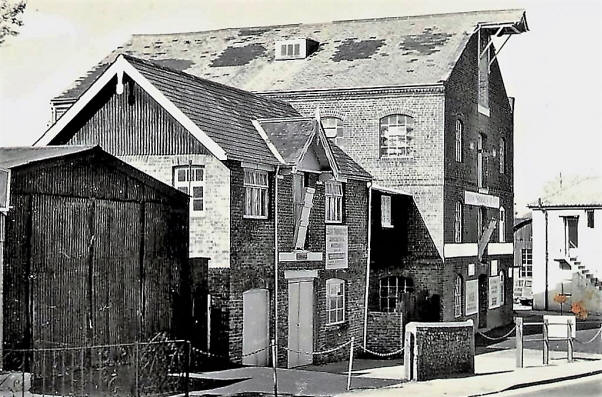

Harebeating Mill, Hailsham (1930) |

Staple Cross Mill, Sussex (1931) |

|

In his prime he would average 70 miles a day,

sometimes more than 100 for a good mill, but now, at

83, he paces himself; lean and tanned, he still

manages a lively pace awheel, but reckons that 35

miles a day is quite enough, after all, a chap wants

to enjoy both the journey and the destination. One

week was the longest holiday period, and he

travelled as far as he could within the time,

gradually covering the Midlands and the south west.

First he concentrated on windmills, but by the late

1930s he had more or less run out, so he widened his

scope to watermills.

“Windmills were always prominent and more easily

destroyed than water mills. I like windmills but I

gradually got to like watermills more. They are

often hidden away in remote and very quiet places

and there is always running water. I got bitten by

them really, they were magical places. Often they

were at the end of little narrow tracks, and to see

them working was remarkable, the thundering wheel,

water rushing over or under, and the whole building

vibrating with the force of machinery”. Yet most

people didn't even know they were there.

“It just got hold of me and I visited as many as I

could.” He became a member of the Wind and Water

Mills Section of the Society for the Protection of

Ancient Buildings when it was inaugurated in 1934,

and now he belongs to four mill groups and is an

honorary member of the Hampshire Mills Group. |

|

Emsworth Town Mill |

Arthur is one up on many of the younger members in

that he was privileged to see quite a number of the

mills when they were working. Sadly, many of the

mills in his photographic collection exist no more.

“There were actually very few windmills in

Hampshire and I have seven of them on film.”

Arthur is a retired joiner whose family have been

builders in Gosport for many years and he has a

craftsman's interest in the skilled woodwork which

went into building the mills.

"Each mill has its own

character and is different in some particular. They

were all hand-built with local materials of stone,

of bricks, and quite a lot were all wood. Massive

shafts, usually of pine, great spurwheels of oak, up

to ten or 12 feet in diameter were fitted with

applewood teeth which had to mesh accurately with

bevel gears to drive the stone nut. There were

ingenious methods of disengaging the drive to the

stone or stones; other machinery, such as the flour

dresser, was driven off the main shaft. When the

mill was in gear and grinding the miller could get

on with other jobs, the hopper feeding the stones

automatically, a little gadget called a damsel, an

iron forging agitating the shoe of the under-driven

stones. An alarm bell rang if the stones ran dry.

After the church, the mill was the most important

secular building to exist, from medieval times right

up to the end of the 18th century, and many villages

had two mills." He believes there may be as many as

60 windmills in England in working order or capable

of working, and among them just a few still working

commercially. Six windmills at least have been

restored to near working order by the Norfolk Mills

Trust. Many more water mill buildings have

survived, well over 100 of them capable of working. |

|

There are heroic tales of the hard work put into

restoring mills, much of it by volunteers, and

Arthur knows of a young man and wife hard at work

restoring a Dorset mill right now, a project that

has taken them two years so far. It is an expensive

business – putting two new pairs of sails on a

windmill costs £10,000. Counties with lots of

rivers and streams have plenty of mills, but with

water extraction and falling water tables, quite a

few have been left dry of motive power. Every

village in the Meon Valley had a water mill at one

time. Best known for grinding the flour for bread –

often a bakery was part of the complex – mills have

also been used for making gunpowder, especially

around the Medway in Kent, or for grinding stone for

pottery making in Staffordshire. There were fulling

mills where cloth was prepared, particularly in

Gloucestershire, many were used for preparing animal

feed, and other mills produced paper. Bere Mill at

Whitchurch, Hampshire, once produced paper for the

Bank of England. Off the A34 between Winchester and

Newbury is a fine and rare silk mill, open to the

public, where a water wheel occasionally drives some

of the machinery for spinning. The death knell for

most ‘green’ powered flour mills came with the

advent of steam and mass production using huge steel

rollers, but the ones that are left are seeing a

revival of interest. |

|

Barton Mill, Basing |

Waltham Chase Mill |

|

Arthur is pleased by this and was delighted by the

goings on at Bartley on the Sussex-Kent border last

year. Wheat was cut, ground in the nearby mill and

baked into bread next door, all within seven hours –

you can't get fresher bread than that. So many

miles were covered by Arthur's second bicycle on the

mill quests that it got metal fatigue and the frame

actually broke in half while he was riding it in

Dorset. He found a new frame and used all the other

bits from his old bike, including the hub gears, and

carried on. Then his much prized, three-inch

dropped handlebars (known as Lauterwassers, he

learned from author Eric Newby) snapped off. Since

then he has had to make do with flat ones, which he

doesn't like as much. He admits to having any

amount of spills from his bike and once ended up in

Hastings Hospital having been found unconscious in

the road. "Cycling is not as pleasant as it was,

because of the motor traffic, but that does not put

me off. I am out on my bike every day, rain or

shine." His favourite mills are Hockley Mill near

Twyford, in Hampshire, beautifully kept by its owner

though not working, and Sheffield Mill, Furners

Green, East Sussex, smaller scale with a huge pond.

When he was last at Sheffield the wheel-buckets of

the overshot mill (the water hits the wheel from the

top) were gone but the 18th century machinery was

still in fair order inside. Not long ago he saw

that mill house and mill were for sale, but it was

just a little beyond his reach – £600,000!

The skills necessary to restore mills to working

order have not died out, and there are some six or

seven professional millwright companies in the

country, including one busy engineering concern in

West Sussex, E Hole & Son Ltd of Mill Road, Burgess

Hill, which operates mainly in Sussex and Kent and

has done work on Eling tide mill near Southampton,

and on Bursledon windmill in Hampshire.

This article was written in 1994, and it is

fascinating to see how the mills have fared since.

Congratulations to Tony for ensuring that the photos

have survived. Editor.

|

|

|

|