|

|

|

Page 6 |

Newsletter 116, Spring 2017 © Hampshire Mills Group |

|

Visit to Headley Mill

Nigel Harris

This report of mine was published recently in SPAB

"Mill News" #149 in October 2016. Headley Mill is

not currently open to the public so my thanks go to

Richard Ellis for giving me a guided tour and to

Andy Fish, Chairman of HMG, for his help in setting

up the visit.

|

|

|

|

|

Built astride the River

Wey, Headley Mill near Bordon was a family-run

watermill on the site of a manorial mill site dating

back over 700 years. The mill and mill house, both

of stone, face SE and form an attractive continuous

range. The west end of the mill is considered to be

16th century and the centre is much

older. About 1800 part of the house was rebuilt and

the open water wheel covered in, major

reconstructions took place to the fabric of the

mill, and much of the milling machinery was

installed.

|

The stone floor, notice the stone

crane on the right

The water from the

mill pond powers a 12½ft (3.8m) diameter by 7½ft

(2.3m) wide breastshot waterwheel, dating to 1926.

The wheel drove four pairs of millstones, three

French burr and one Peak (two pairs at a time). The

spur gear train consists of an iron pit wheel which

is 9ft (2.74m) in diameter with oak teeth. This

drives an iron wallower which in turn drives the

upright shaft on which the iron 8½ft (2.6m) diameter

great spur wheel is mounted (photo below left).

The great spur engages the stone nuts which have

teeth of beech wood. Two gears driven by the crown

wheel drove auxiliary machines such as crushers,

rollers, and sack hoist.

The Armfield grain

cleaner (below centre) and 3 centrifugal

dressers (one, below right) were electrically

powered and added more recently.

|

The bin floor

|

|

|

|

|

Members of HMG have been

involved with and have carried out work at Headley

Mill over a number of years. In 1996 they replaced

a main beam of the mill (photo below, by Ruth

Andrews) and in 2006 they replaced the buckets

in the waterwheel.

|

|

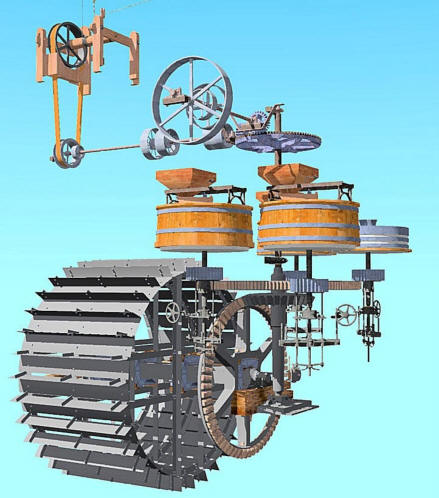

John Brandrick visited

Headley Mill in 2012 and has produced a number of 3D

drawings to record the structure and machinery of

the mill (an example is on the right). These can be

viewed at his website

www.milldrawings.com.

Headley Mill was

working commercially until fairly recently, and all

the machinery and belt drives are still in position.

|

|

|

|