|

The last issue

covered the history of the mill and the mill

building.

This article

will describe the milling machinery left as

it was when milling ceased in 1939.

|

|

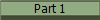

THE GROUND

FLOOR

This is a ground

floor plan of the mill.

There is a single water wheel turning two

pairs of millstones on the floor above.

|

|

In the western

bay of the building there is a small bucket

wheel driving a water pump. It was inserted

sometime after 1921 to supply a tank up the

hill which provided water to the newly built

Station Bungalows. There is evidence that

this bay may originally have housed a second

water wheel. Firstly, there are three

waterways under the building of which one is

likely to be an overflow sluice leaving two

for water wheels. A waterway runs beneath

this bay. Secondly, there is a grain chute

on the second floor in the right position to

feed grain to the stones of a wheel in this

bay and thirdly, there appears to have been

no other use for this large area. |

|

The Water Wheel

The cast iron

wheel is 3.7m in diameter and 1.6m wide,

turning on a circular iron bound wooden

shaft. The wheel was cast in two halves

bolted together and fitted to the shaft by

wooden wedges. This allowed it to be

assembled in the pit without having to

dismantle any of the building. It does not

bear any visible makerís marks. It is

flanked by brick walls. |

|

|

The

Sluice Gate

Here are some

of the iron buckets of the water wheel and

the gear operating an iron sluice gate just

upstream of it, which allowed the miller to

start and stop the wheel.

|

|

|

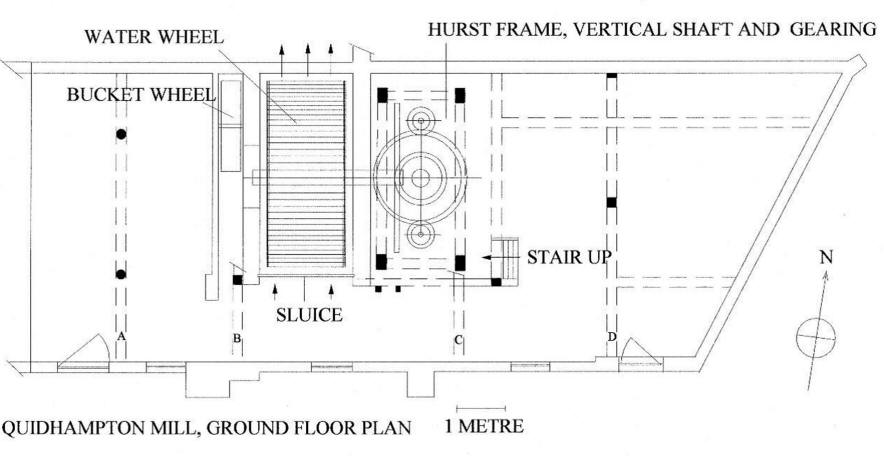

The

Pit Wheel, Wallower

and Great Spur Wheel

The pit wheel

and wallower are cast iron but the great

spur wheel is made of wood. The stone nut

and shaft are of cast iron. The underside

of the stationary bedstone on the floor

above can be seen. It will be noted that

the stone nut and the great spur wheel are

not properly aligned, and the baulk of

timber which acts as the bearing for the

vertical shaft has partially rotted away,

allowing the whole shaft to drop.

|

The view below

from the east shows the iron bound wooden

vertical shaft on its bearing, the wallower,

and the great spur wheel. The pit wheel is

behind. |

|

Tentering

Gear

The turn screw

was used for adjusting the height of the

stone nut shaft and thus the gap between the

stones. |

|

|

THE STONE FLOOR

The Mill Stones

This is one of the two

running stones, 117cm in diameter. It is

probably made of several pieces cemented

together and bound with iron hoops. The

running stone had to be very accurately

balanced about its centre to avoid

vibration. This was done by placing lead

discs in any of the four recesses cemented

into the upper surface.

(Editor's note : all

the stones furniture seems to be missing.) |

The inscription on the

recess cover reads:

MILLSTONE BALANCE PATENTEES

CLARKE AND DUNHAM, MARK LANE, LONDON, 1869

|

|

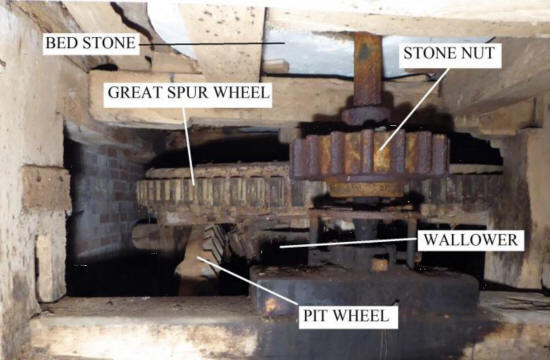

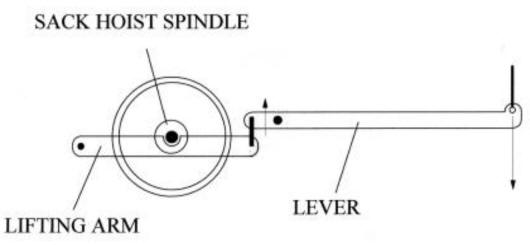

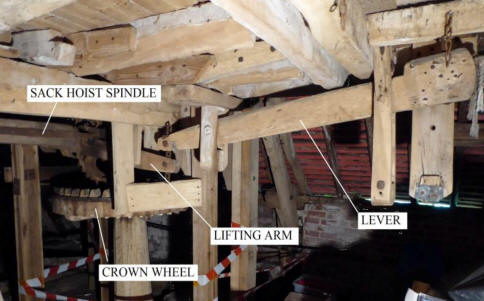

The Crown Wheel and Sack

Hoist

|

The wooden crown wheel

is redundant. A smaller cast iron wheel has

been inserted above it, engaging with a

vertical cast iron wheel which drives the

sack hoist spindle. By putting tension on

two or three turns of rope around the

spindle from the bin floor above, the

operator could use the power of the water

wheel to lift heavy sacks of grain from the

ground to the second floor.

|

|

The lifting arm is

connected by a lever to a cord leading to

the floor above. Allowing the weighted lever

to fall lifted the vertical cogwheel off the

cast iron crown wheel to disengage the sack

hoist.

|

|

|

The Bins

One of two

grain bins viewed from the first floor. The

spout for feeding grain into the eye of the

runner stone is missing. |

One of two

bins on the second floor for feeding grain

into the hoppers. |

|

THE BIN FLOOR

One of two

pulley blocks for the sack hoist rope. |

The

upwards-opening trap door for the sack

hoist. The hinges are made of leather. As

a safety measure, the doors close by gravity

when the sack has passed through.

The east end

of the bin floor (left). A new purlin can

be seen on the left. The old ones have been

left lying on the floor. This is where the

millerís little daughters played Ďhousesí in

the 1920ís. |

| |

|