|

|

|

Page 6 |

Newsletter 119, Winter 2017 © Hampshire Mills Group |

Country House Tour in Northern Ireland

Angela Smith |

|

In August, Nigel and I

visited Northern Ireland to join a group trip with

the AIA’s Heritage of Industry, visiting Country

Houses with the aim of learning about the technology

rather than the grandiose interiors. What had

caught our eye was the promise of such gems as “saw

mill”, “corn mill”, “gas manufacture”, and other IA-related

subjects. The tour was being led by Prof Marilyn

Palmer, the AIA’s Honorary President, and was

commencing on the afternoon of Monday 7 August with

the last visit on the morning of Friday 11.

Participants had to make their own transport

arrangements to Belfast. We decided to travel on

the Saturday, Flybe from Southampton Airport, to

give us time for independent sightseeing. We were

in the Titanic Quarter by 11:30.

On Sunday we had

planned to visit the Ulster Folk and Transport

Museum at Cultra, a mere 20 minute train ride. The

morning was wet so we spent that in the excellent

Transport Museum before taking the shuttle bus to

the Folk Museum. Like open-air museums such as

Weald & Downland, this is composed of relocated

buildings from all over Northern Ireland and has a

“village” and rural exhibits, three of which are

mills.

Straid Corn Mill:

The site map describes this mill as “currently

closed” – it looked like it had been neglected for

some years. The large wheel and leat were covered

in vegetation so we didn’t bother trying to take any

photos. The mill, consisting of several stone,

slated, single, and 2-storey buildings, comes from

Straid near Ballymena in Co Tyrone. It was part of

a large farm complex which also had two scutch

mills. A mill had been on the site since 1785 but

was rebuilt in 1852. It ceased production after WW2

following a reduction in operation due to

competition from larger mills. It was dismantled

and moved to the museum in the 1980s.

Gorticashel Flax

Mill: Like Straid Mill, this single 2-storey

building has also seen better days, with the wheel

very overgrown. It had been a scutch mill from Co

Tyrone, but the website gives no details of its

history and there is no guide book available. Scutching

is the process of extracting linen fibres from flax

stems by being passed through cogged rollers. It

was a highly dangerous occupation as workers were at

risk from machinery that could not be stopped

quickly, the air was thick with dust, and there was

an ever-present danger of fire. On at least two

occasions this mill had been severely damaged by

fire.

Coalisland Spade

Mill: Although in a good state of repair, this mill

was not manned so we were unable to visit it and the

adjoining building which once housed 4 finishing

shops. The mill, from Derry in Co Tyrone, was built

in the 1850s and moved to the museum in 1960.

|

|

|

|

It is a single storey

building constructed mostly of stone, with the back

gable wall and chimney of brick. A wooden launder –

which was dry – leads from a small dam. There are

two external breast-shot wheels. A massive hammer

in the mill is tripped by a cast iron wheel driven

directly from the larger water wheel. I was able to

take a couple of flash shots through the mill

window. |

|

|

|

Between 1800 and 1900

in Ireland, the spade was the most usual tool of

cultivation. Ulster spades had welded sockets and

spade mills were erected to mass-produce them. A

skilled spade maker could make up to 120 varieties

of spade, in up to 5 sizes. This mill was operated

until the 1950s by one family over five generations.

The Tour

On Monday we met up

with the group after lunch. We were led by Bill

Barksfield and Prof Marilyn Palmer and there were 18

other participants. The afternoon’s visit was to

Mount Stewart which only re-opened 3 years ago and

parts are currently still undergoing major

restoration. As I was unable to glean much

information about the mills and so on seen on the

tour, I am grateful to Marilyn for giving permission

to use her tour notes for some mills.

Myra Castle Farm

(south end of Strangford Lough): Tuesday morning

saw us making a private visit to Myra Castle Farm,

owned by David Good who guided us around. The main

house was built about 1844 and the model farm

complex was linked to the house by a meandering

“cut-and-cover” tunnel built for the servants,

top-lit by ships’ portholes, though it was mostly in

darkness. Apart from the water wheel, the site also

has a small lime kiln, weighbridge and almost

complete estate acetylene gas works.

|

|

The large but narrow

water wheel had been installed to power farm

machinery including a circular saw sited nearby in

an open-sided shed and threshing machinery in the

adjacent barn.

|

|

Water power proved

inadequate because there is also a single cylinder

horizontal steam engine with an upright steam

boiler. Some line shafting survives. Projecting

from the servants’ quarters at the rear of the house

is a circular roofed horse gin which was apparently

built to power a butter churner in the dairy inside

the house. This was built sometime after 1874 but

was disused by 1900. |

|

|

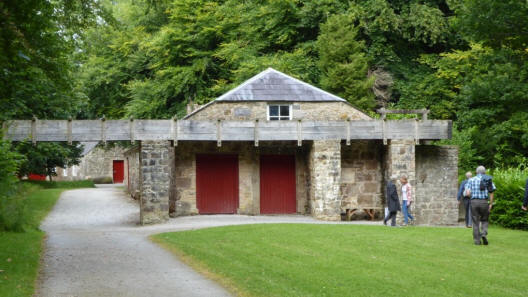

Castle Ward Estate

Yard (south end of Strangford Lough): After the

farm we then moved on to nearby Castle Ward,

remarkable for the fact that it has two differing

frontages. The 1st Viscount Bangor wanted a

Classical frontage while his wife fancied Gothick.

So both the exteriors and interiors reflect these

tastes. It was built in the 1760s at a cost of

£40,000.

Our very

knowledgeable guide, Martin Gibson, told us that

tide mills are rare in Ireland, although several

were constructed around Strangford Lough during the

1800s. He said that the earliest tide mill was

thought to be at Nedrum, further north on the lough

on a monastic site, dating to around 700AD, and had

a “vertical axis propeller”.

Unlike other mills

seen on this tour, there are a number of useful

descriptive panels with text and diagrams in the

barn adjacent to the mill which I have drawn on for

this section.

|

|

The first mill at

Castle Ward was built in the early 1700s and was

used to grind oats, barley and wheat into meal and

flour. It was initially a tide mill operating from

the tidal Strangford Lough which filled a millpond

at the rear at high tide.

A 1744 description

of the operation by Walter Harris says: “On the bay

that opens to the garden is a singular contrivance

for supplying a mill with water. A dead wall is

carried across the gut in which are two arches and

in them two flood gates fixed, the one to admit the

tide, the other to keep it in or let it out, as

occasion serves. By this means a corn-mill is

perpetually supplied with water which can never fail

as long as the tide flows here.”

|

|

Martin explained that

the bottom of the waterwheel was not far above low

water level so, in the 1800s, it was converted to

normal stream operation from the spring-fed large

ornamental lake on the estate, Temple Water, with

channels cut down to the mill.

A corn-drying kiln was

built in 1800. During the 1830s the corn mill was

enlarged and a threshing mill added. New grinding

machinery and a replacement waterwheel were

incorporated, powered exclusively from the Temple

Water without tidal assistance. The machinery was

again renewed in the 1870s but, by the early 1900s,

the mill had ceased operation. It lay dormant,

gradually falling into disrepair, until 1991 when

the National Trust began to restore the mill to full

working order again.

|

|

|

|

The complex houses a

kiln, thresher, winnower and two pairs of

millstones. Remains of the tide mill can still be

seen in the façade. Adjacent to the corn mill is a

sawmill in a barn (left), preserved but not working.

On our tour of the

house I had inspected an old map and spotted a

“Windmill Hill” not far from the estate and asked

Martin about it. He explained to everyone that

there was a line of post mills but, due to being

hand turned, they fell out of use. There is a

preserved smock or tower mill somewhere around the

lough. |

|

Castle Coole (near

Enniskillen): Built between 1789 and 1798 for the

1st Earl Belmore. He commissioned an ice house so

that he could preserve meats and have cool drinks

and ice cream. He built a pump to bring water from

Lough Coole to the new house which is located in a

small octagonal pump house, pumping water to a tank

off the servants’ tunnel from where water was

carried into the house.

|

|

Florence Court: This

‘family home’ was built c1756-64 but suffered a

severe fire in 1955, not long after the National

Trust acquired it. It has now been fully restored.

In the grounds are a sawmill, hydraulic ram and

icehouse. The single storey stone sawmill has a

metal high breast-shot wheel manufactured by William

Maxwell in 1848, and fed by a launder, crossing a

main path, with water from the Larganess River.

The mill was

established in 1840 by the 3rd Earl of Enniskillen

to process timber from the estate. It produced

rough-sawn timber Finished products such as

cartwheels would have been completed in the

carpenter’s shop north of the sawmill.

There is also a

Bark House where bark stripped from the wood was

crushed to extract tannin. The drive for the saw

bench comes from a cog wheel off the pit wheel. The

saw bench was converted to electricity after mains

power arrived about 1951. There is a small electric

motor in a recess in the wall which probably drove a

small free-standing saw bench.

|

|

|

|

|

The Argory: There

were at least three different sources of water for

the house. Outside the east garden pavilion is a

submerged water pump (by W Davis, Navan) presumably

raising water from a well, driven by a horse gin

which is missing its swivelling drive arm. The west

garden pavilion is closer to the river and contains

a manually-cranked water pump, presumably for

pumping up river water. There was also a rainwater

collection tank which may have been the source of

water for a manual pump in the middle of the garden

south-west of the laundry.

|

|

The only feature which

we saw which might be associated with water supply

was what appeared to be a sluice mechanism near the

river with a pipe coming out of it which then

disappears under the grass towards the house. There

was insufficient time to investigate further as we

then had to make our way back to George Best Airport

and the flight home.

All in all, a very

interesting visit to many properties with some mills

thrown in for good measure!

|

|

| |

| |

| |

| |

|

|