|

I would like to thank HMG members Imogen and Douglas

Lyndon-Skeggs who invited us to Soberton Mill on 14

January 2018 to show us the sluice repairs and

newly-dredged headrace, which has enabled the mill

to regain its water supply. They very patiently

also let us re-visit the mill and take a few photos.

This Georgian mill (below left) is unusual because,

although being unrestored, it is securely roofed and

moderately safe to enter. The milling machinery is

long gone, but a few tantalising clues to its

configuration remain.

|

|

|

|

We entered the stones floor (above right) from the

gravel drive outside the much altered and enlarged

mill house, and descended to the flour floor where

we found our first curiosity. The ladder from the

stones floor descends into a circular brick

compartment (below left). This feature is most

unusual for an English mill. It looks as if it

might once have housed the wallower and great spur

wheel. The brick section supports the bearings and

tentering gear for two stone spindles (below

right). We do not understand the purpose of the

windows, but they may have been added after the

milling machinery was removed.

|

|

|

|

Outside the circular feature there are pulleys for

belts from the Armfield turbine which was installed

in the early 1930s in the external wheel pit. It

occurred to me later looking at my photos that the

original wooden floor at this level was missing,

exposing what looks like it could have been an older

waterway or even a wheel pit.

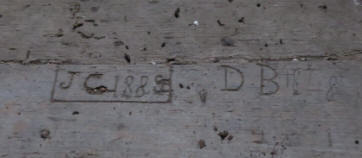

We then ascended to the bin floor (below left) where

things were much more familiar. As Imogen pointed

out, the massive timbers throughout the mill are

once again from a wooden ship (think Chesapeake) and

there are several interesting initials and dates,

for example ‘DB 1848’, ‘J Cal 1888’, and ‘R Smith’

(below right).

|

|

|

|

|

|

Imogen and Douglas aim to install a turbine and

generate electricity but for now the old turbine (a

12inch single-head side gate ‘River Patent’ Armfield)

is clearly visible below the newly-invigorated

waterfall in the wheel pit (above). Imogen tells me

that the turbine and a generator was installed by

Bernard Wharburton-Lee, the first VC of the second

world war, who was a massive enthusiast and lived at

the mill house. He died at Narvik in 1940 aged 44

and is buried in Norway. He was the last person to

do restoration work of any note on the millstream.

He straightened and concrete-lined the part of the

leat close to the house and made extensive tunnels

for the waterways under the drive to pass water

through the turbine or overflow through a channel

and then back into the river downstream. The

generator produced the first electricity for the

house and the turbine was later turned into a

water-pump to boost the low water pressure in the

house.

|

|

|

|

Having satisfied ourselves with the mill, Imogen and

Douglas and the dogs took us a walk up the very long

embanked Tudor head race. The original mill was

built well above the flood plain of the Meon and the

leat was utilised for water meadows.

In the past, dredging was done by horses dragging

square chains to raise the silt and flush it

downstream. These chains are still in the mill (below

left). Over

the years the leat had become very silted-up and the

sluices had decayed.

|

|

|

|

Walking up the embankment now, it is very hard to

believe the amount of work that went into dredging

the channel. The masses of silt dredged out of the

waterway have been cleverly contoured to look like

part of the embankment. The

difficulty in using a digger is the need to avoid

piercing the clay lining. The

picture above right shows the final moment when the

earth dam holding back the water was about to be

removed. |

|

|

|

One of the reasons that the mill lost its water

supply was that the sluice to the water meadows

decayed. The embankment was strengthened and the

site of the sluice reinforced.

Much of the work was done by the river-keeper who

trained at Sparsholt. He also works on the Kennet

and Avon Canal and salvaged some of the sluice works

for the vertical sluice gates from the waste bins of

the canal. They were restored by the blacksmith in

Farringdon and installed on-site by him. The

work also included completely rebuilding a brick

spillway. |

|

|