|

|

|

Page 5 |

Newsletter 125 Summer 2019 © Hampshire Mills Group |

|

Eureka-style grain cleaners – air flow through a

typical unit

Nigel S Harris & John Brandrick

Drawings © Nigel Harris & John Brandrick. Photos by

Nigel Harris |

|

The S Howes Company of Silver Creek, New York

manufactured the “Eureka” type grain cleaning

machines. Numerous examples of this

machine exist in the UK. After we studied the

construction of some of these machines, we thought

it might be useful to offer some conclusions on the

air flow through a typical unit.

|

|

These machines were widely copied by other

engineering firms and also made under licence. They

exist in various forms, often as scourers, smutters,

and separators, or brush and finishing machines.

The various constructions tend to share similar air

flow routes and purpose with regard to the function

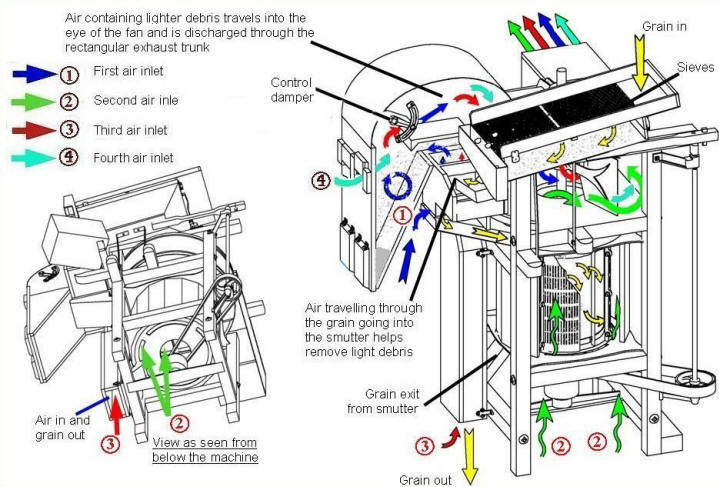

of the air flowing through them. Figure 1 (right)

shows a typical Eureka grain cleaner unit that we

shall consider.

This machine utilises air currents to remove from

the grain both dust and other impurities such as

chaff, straw, shriveled grains and so on. The

construction of the machine to be considered has a

‘smutter section’ as well as an initial screening

stage via shaking perforated metal sieves.

|

|

|

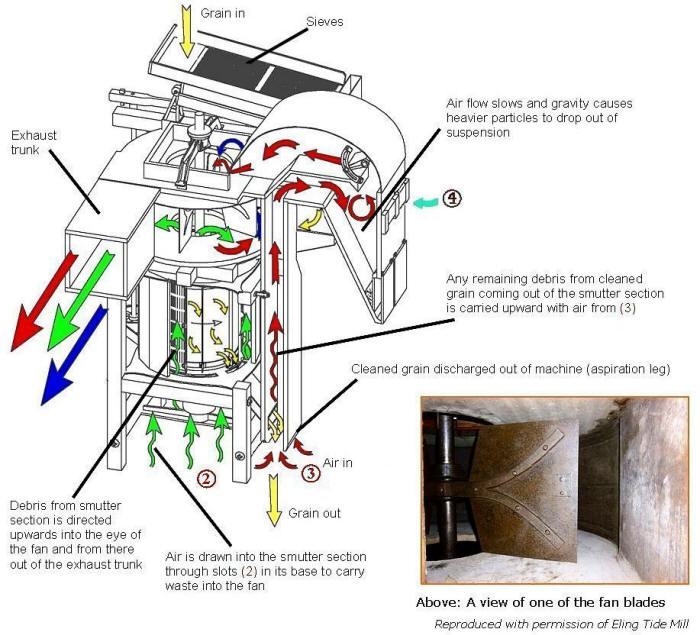

There are four air circuits (one being variable)

that take place, before, during, and after the

smutter section. The air flow circuits look fairly

complicated as shown in figures 2 and 3, which are three-dimensional

views of the air flows.

This arrangement appears to be a typical arrangement

although there are noted to be some differences

depending on the model and type of machine. |

|

|

At the heart of the Eureka is a large fan, an

example of an actual fan blade can be seen in the

picture in figure 3, these are fairly large and

flat. The air pressure just at the entrance to the

fan will be the lowest in the machine and will be at

atmospheric pressure at the inlets

1, 2, 3

and

4. The fan acts as a form of compressor and on its

outlet side it discharges to atmospheric pressure in

the exhaust trunk. |

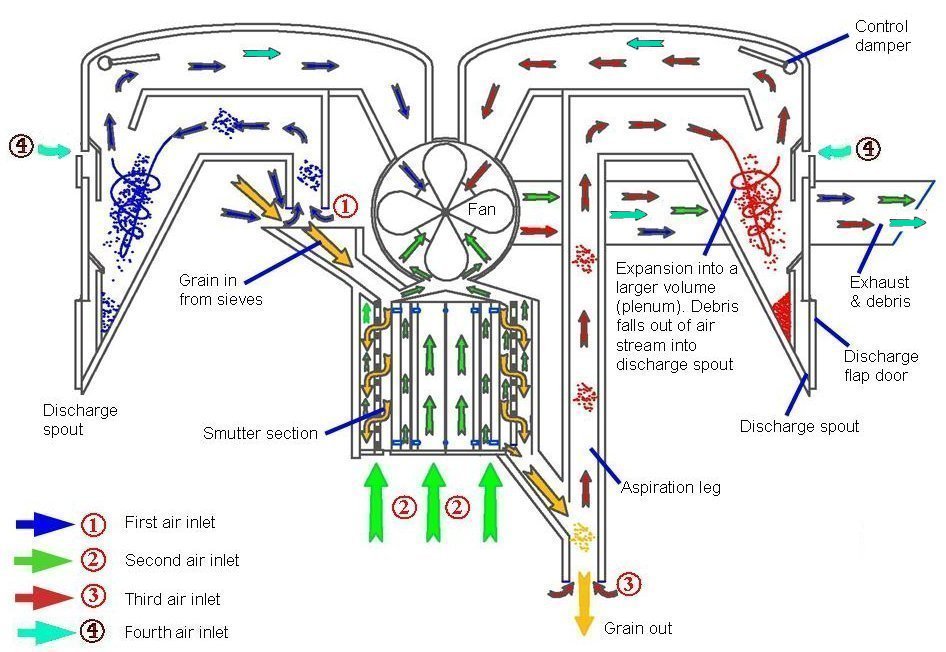

Figure 4 (above) is a simplified schematic showing

the route of the air circuits. (This schematic does

not include the layout of the shaking sieves.) Note

the aspiration legs. Aspiration, or separation by

ascending air currents is used to remove light

particles from the grain. The principle involved is

that particles of different size, shape and specific

gravity have different “terminal velocities”.

Examples of terminal velocities are given by

Lockwood[1], for example. 500 to 700ft per min for

chaff, 700 to 1200ft per min for light straw and

seeds, and 1150 to 1930ft per min for wheat. Wheat

has a higher terminal velocity than light

impurities, so that if a mixture of wheat and light

impurities is dropped into an air current rising at

a suitable speed the wheat will fall through it and

the light particles will be borne away.

A particular feature of Eureka machines is the

expansion chambers or plenums. There are two of

these being vertically separated and alongside each

other in the triangular shaped section. As the air

containing debris is drawn from the duct (or

channel) into the expansion volume the air flow

slows. Solids being carried by the air tend to fall

out of suspension and fall into the tapered

discharge spout in the bottom of the chamber.

Control dampers are provided to adjust the air

throughput.

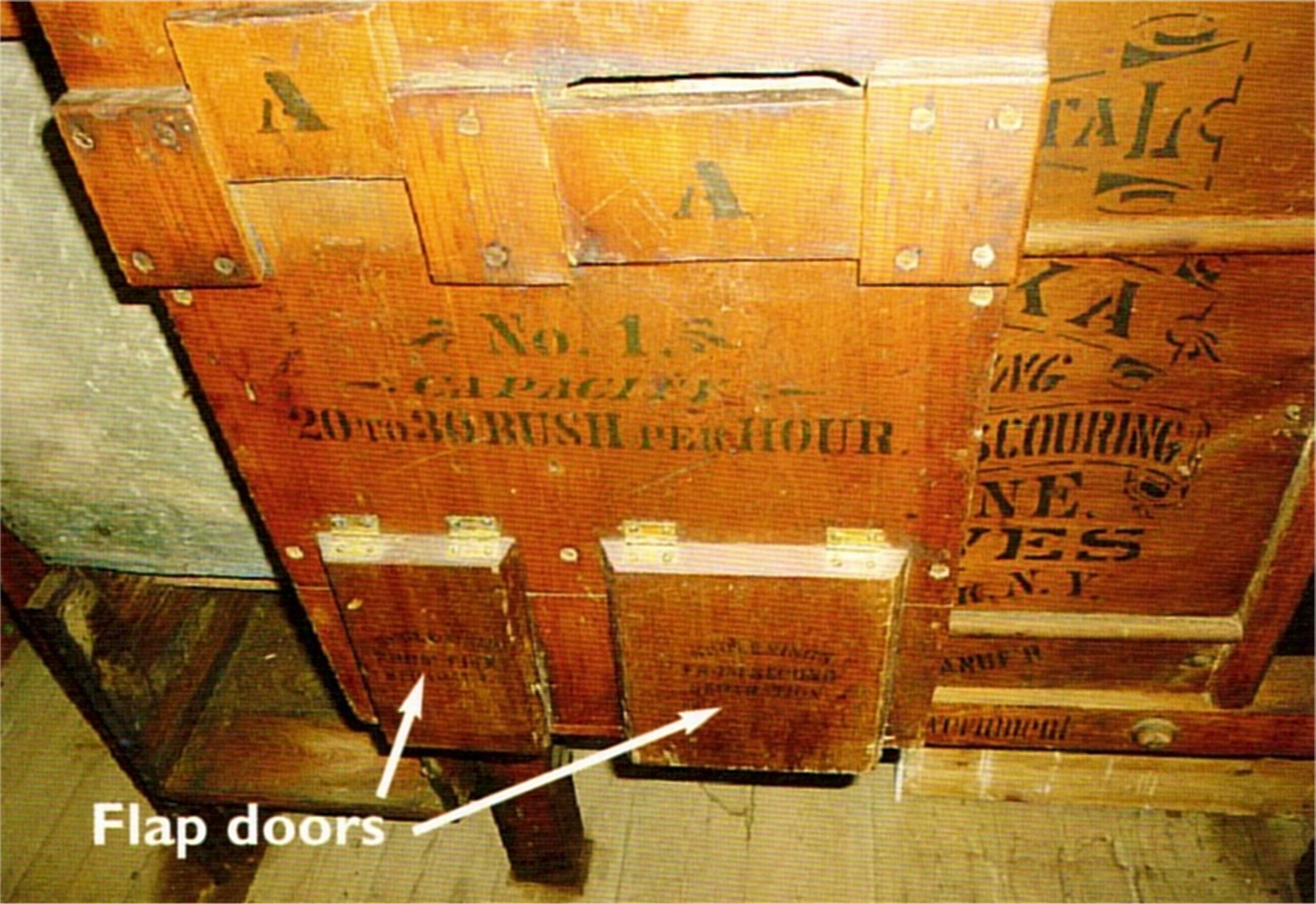

The debris, which falls into the discharge spout,

remains there until the weight of the accumulated

debris exceeds the force of atmospheric pressure on

the doors of the spout – see figure 5 – whereupon it

falls out of the spout. Also shown in figure 5

are the two air inlet slides (marked 'A'). These

vary the amount of air that can be admitted to the

plenum. If used, air entering the machine here

assists in the removal of light debris from the

plenums towards the fan.

|

Figure 5: The discharge flap doors and air inlet

sliders (marked 'A') on the discharge trunk |

Figure 6: A view inside one of the two air ducts

above the plenum.

Both photos Courtesy of Ifield Watermill, West

Sussex |

|

Figure 6 shows a view inside one of the two air

ducts above the plenum. Note the smooth curving

roof and bottom of the channel. Curves, rather than

abrupt right angle bends, help reduce irregularity

in the air flow. The highest air flow will be in

the centre of the duct with the lowest at the sides

due to drag (friction) with contact along the walls.

Note that the drawings have been based on

information obtained from various sources (see for

example references [2] to [5]), and via external

inspection of various machines. However, both John

and I would welcome sight of any photographs that

show internal details.

References:

[1] Lockwood, J F (1945), Flour Milling. The

Northern Publishing Co Ltd

[2] Greey, W & J G (1901), Greey Toronto Mill

Furnishing Works: Illustrated Catalogue p43 to

45

[3] Robertella, L (2013), http:/www.lousweb.com/Castle%20Valley%20Mill/eureka_brush_machine.htm

and private communications.

[4] Voller, W R (1892), Modern Flour Milling

p53 and 79. John Bellows.

[5] Grimshaw, R. (1882), The Miller, Millwright

and Mill Furnisher p275. Howard Lockwood.

|

| |

|

|

|

|