|

|

|

Page 2 |

Newsletter 131 Winter 2020 © Hampshire Mills Group |

Fallgate Mill

Ruth and Keith Andrews

|

|

|

|

The

buildings of Fallgate Mill (also known as Fall Mill)

at SK 354623 probably date from the early 17th

century and have been restored, with a lot of

internal gearing still intact. There were two wheels

at opposite ends of the main building, one of which

has been ‘restored’. The position of the other wheel

is detectable from score marks on the mill wall and

a filled-in aperture for the axle. Originally water

was brought to the mill through a long leat from a

weir on the River Amber about half a mile upstream.

There was a mill pond, now filled in, above the

site, and some water probably also came from a lead

mine sough.

|

|

|

|

In

1918 the site was acquired by the Clay Cross Company

who used the mill for grinding fluorspar. In 1925 a

siding from the Ashover Light Railway was laid to

run in front of the buildings. The mill continued to

be used until the 1950s and then fell into

disrepair. It was the last of seven that worked in

the Amber Valley.

In

1985 the site was taken on by Ashover Parish Council

and some restoration work was carried out; more work

has been done recently prior to the conversion and

sale of the building as a residence.

Information from Derbyshire Historic Environment

Record

https://her.derbyshire.gov.uk/Monument/MDR5136

Fallgate Mill and the Clay Cross Company

The Clay Cross Company, founded (at Clay Cross!

south of Chesterfield) in 1837 by George Stephenson,

produced lime for roadstone, concrete, and so on.

|

|

In

1919 the Overton Estate near Ashover was purchased

for its valuable mineral deposits, especially

limestone and fluorspar, and a quarry was opened at

Fallgate. The Ashover Light Railway was constructed

to link the quarry to the Clay Cross works. A

steam-powered electricity generating station (‘power

house’) was built next to the mill in 1924 to

provide power for the quarry. A siding from the

railway served the mill and power house.

|

|

Fluorspar, composed of calcium and fluorine (CaF2),

is used in a wide variety of chemical,

metallurgical, and ceramic processes. and was

generally ground at a large plant south of the

quarry (see map). Some customers required it more

finely ground, and this was done at Fallgate Mill.

It was dried by a gas-fired kiln (which replaced a

coke-fired one) in the red pantiled front part of

the mill, and then ground using the water-powered

millstones, and loaded into wagons on the siding to

be shipped out. At least one of these millstones is

embedded in the kitchen floor.

|

|

The power house, built with materials

from demolished buildings on the same site, with

large cast iron windows.

TInformation from

The Ashover Light Railway,

by

R Gratton and S R Band,

(Wild Swan, 1989)

|

|

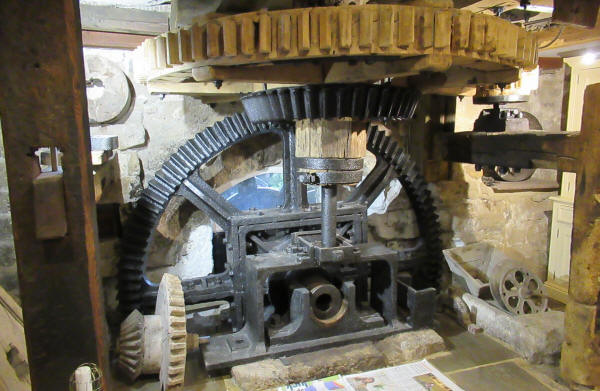

So here are some interior details.

|

(Above) Details of wear on the teeth

of the great spur wheel and wallower

|

(Right) The kitchen

floor has recently been relaid using worn out

millstones. The nearer one must have been used for

grinding fluorspar.

|

|

|

|

|

|

|

|

(Above left) At first

glance, this is a bedstone, but it is actually an

upside down runner stone, which at present is

letting a cold draught into the living room

upstairs.

(Centre and right)

The restored stone spindle looks OK, but the stones

above it are clearly not a matching pair. Also the

layshaft and the crown wheel have been heavily

‘restored’ and fossilised by being cemented into the

wall.

|

|

|

|

So

much restoration work has been carried out a various

times that it is hard to see what the stones were

like when they were in use.

At

the other end of the building the missing waterwheel

drove an upright shaft, which is still in place

along with its wallower. This is the only part of

the machinery remaining on that side of the mill.

|

|

Externally there are also interesting features, and

quite a lot of work to be done.

The

cosmetically restored waterwheel needs some remedial

work. At present the penstock is not attached to

either its supports (which appear to be railway

track) or the building, and has a lot of wood in its

construction. Also, the new wooden bucket boards are

too short, and the sole plate is completely missing,

although its bolts are clearly visible.

|

|

|

|

The

easiest immediate task will be to fit a new guard

rail around the wheel pit.

|

There are various other

interesting artefacts around like this wire machine,

which is on the site of the other wheel pit (note

the axle hole); also outside are a number of

millstones and part of an axle bearing. |

|

|

|

I’m

sure several people reading this are already

dreaming of a work party! Ruth and Michael bravely

said anyone is welcome to visit; you can contact

them through me. Finally I am very grateful to them

for freely giving us access to their new home and

spending so long showing us round – while they

should really have been continuing to move in and

doing more unpacking!

|

|

|

|