|

|

|

Page 3 |

Newsletter 132 Spring 2021 © Hampshire Mills Group |

|

Lumsdale Valley Mills

Ruth

Andrews

Photos by Keith and Ruth Andrews, taken in 2017 and

2020

|

|

I

have had some information for this article since

Keith and I visited it in 2017, but I have only just

found out enough to write about the whole area. Lumsdale

is a fascinating example of how a fairly

insignificant stream tumbling down a rocky valley

near Matlock became arguably one of the ‘best’

water-powered industrial sites in England.

|

|

It

provided power for a sawmill, corn milling, fulling,

lead smelting, bone grinding, grinding minerals for

paints, cotton spinning, and most recently

bleaching, through a complicated series of

watercourses, leats, culverts, and so on which used

water from Bentley Brook.

The

mills and ponds in the Lumsdale Valley are in

a listed conservation area. The Arkwright Society

owns the upper part of the valley and the site was

scheduled as an ancient monument by Historic England

in 2014. The upper part is only accessible on foot

and seems to mostly attract photographers drawn to

the wild waterfalls and tumbled vegetation-covered

ruins. Bentley Brook, the power source for all the

mills, rises on Matlock Moor and has never been

known to dry up.

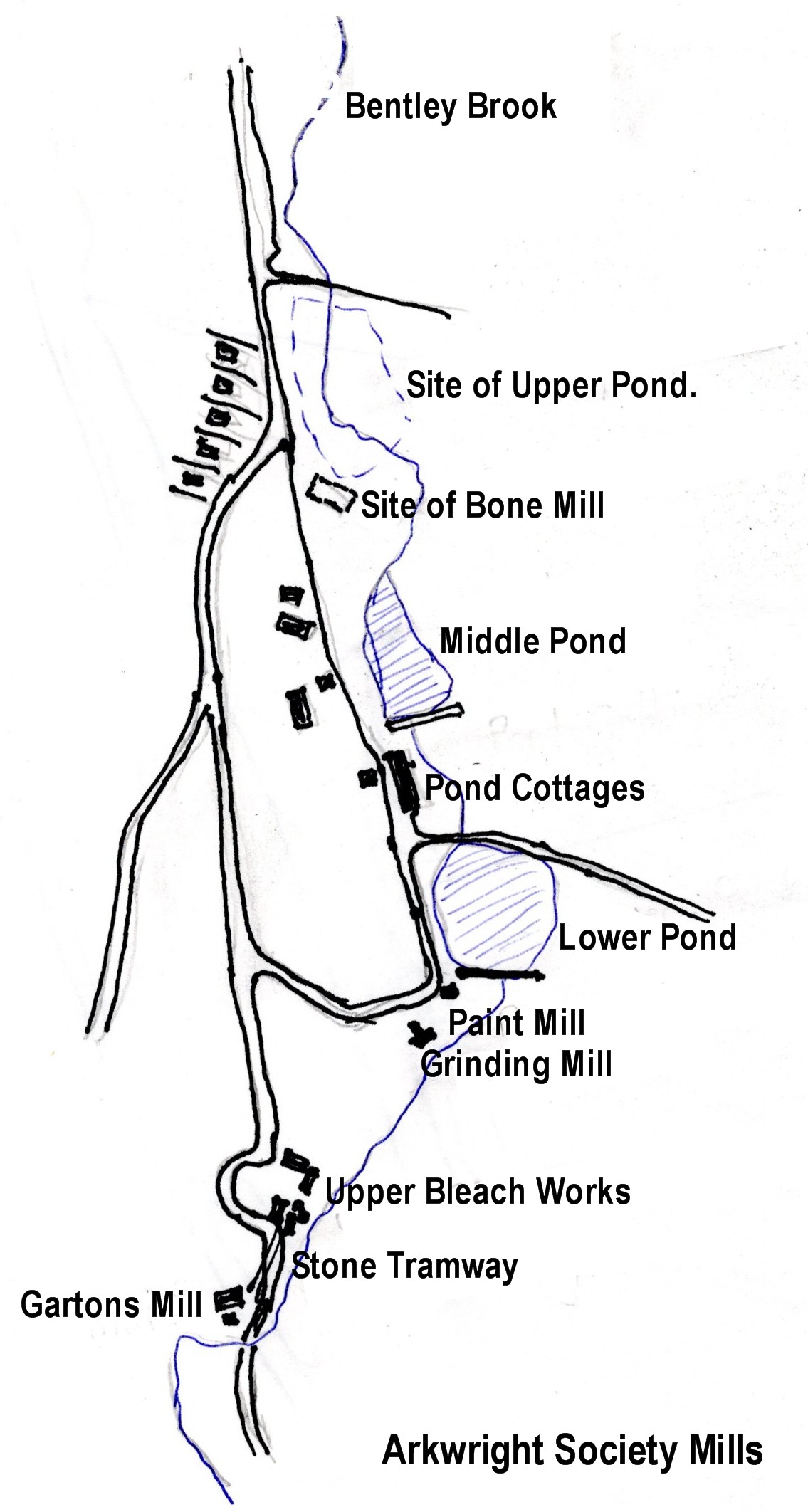

Starting at the top of the site, a water-powered

lead smelter may have been in operation as early as

the 16th century. When the lead industry declined

this oldest building became a bone mill, used

to grind bones for use in making pottery and

fertilisers; its site is now lost in the

undergrowth, along with that of the 1780s upper

pond, whose dam collapsed in 1947. This pond

was built to provide power for an early

cotton-spinning mill (Gartons Mill) lower down the

valley.

|

|

|

A

short distance downhill is the middle pond

(right) which was also constructed in the 1780s to

provide power for Gartons Mill. It had become

completely silted up and was restored by the

Arkwright Society in 2014 with a grant from the HLF.

|

|

|

Below its weir, Pond

Cottages (below left) occupy the site of two

lead smelting cupolas built in 1749. Buildings on

the opposite side of the lane were a counting

house (below right) and ore house. Lead smelting

finished in the 1780s and the buildings were later

converted to workers cottages for the mills further

down the valley..

|

|

|

|

Lower Pond was the site of a quarry until the

1850s when it was converted into a reservoir,

contained by a large stone dam (below left)

which overlooks the steep and intensively built-on

part of the site. Here can be found the paint

mill, which is one of the earliest structures in

the valley, and probably dates from the 1600s when

it was also a lead smelting mill. It later became a

bleaching mill and finally a mill grinding barytes

for the paint industry. There is a single French

burr stone lying abandoned outside the ruined

walls and a beautifully carved circular stone

trough (below right) for bleaching hanks of

yarn.

|

Paint Mill

|

French Burr stone

|

|

It

is hard to separate the ruins of the paint mill from

those of the grinding mill (left), built into

the rock beside a natural waterfall around 1770,

probably as a corn mill, but it also ground red

lead! It has a spectacular wheel pit (below)

which once housed an immense wheel fed by a cast

iron pipe.

|

|

|

Below these rocky ruins the valley becomes steeper

before opening out into flatter land in the valley

bottom.

As

those who have visited the Cromford Mill World

Heritage Site may remember, Richard Arkwright helped

to trigger the mechanisation of cotton spinning when

he invented his famous ‘water frame’. He had the

foresight to patent it. The patent was due to run

out in 1775 so Watts Lowe & Co anticipated this and

built a 3-storey cotton-spinning mill, Gartons

Mill, to take advantage of the newly available

technology. It was they who constructed the upper

and middle ponds to provide a constant water

supply. Two storeys of this first mill have

survived and their construction is very much like

that of the slightly newer mills lower down the

valley.

|

After Watts Lowe & Co went bankrupt in 1813 John

Garton bought the land in the valley and converted

the spinning mill to a bleach works, which became

known as the Lower Bleach Works (right). It

was connected to the Upper Bleach Works

(below) by a stone tramway which hauled

wagons of wet yarn to a drying floor.

Flues led to a large stone chimney opposite

the lower pond. This part of the site is not

currently accessible, and as you can see from the

photo of Upper Bleach Works it is not in a safe

condition

|

|

|

|

|

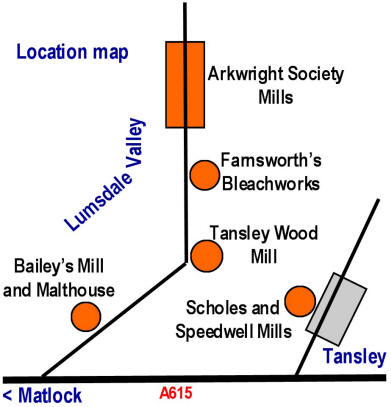

Further down the valley and outside the ancient

monument site (see sketch map on next page) is

Farnsworth’s Bleachworks (right), established in

1792. The walls of the standing buildings and

retaining walls which line the lane date from the

1900s. The main building, with its gable frontage

and central oculus (round window) was a bleaching

croft.

|

|

|

This sketch map shows the locations of mills in the

lower valley and in Tansley, all of which date from

the late 1700s, unlike the much older ruined mills

in the upper valley.

|

|

The

next mill down the valley is Tansley Wood Mill

(see below). The oldest buildings date from

1783, and were used for spinning candlewick yarn

from flax waste. The mill was enlarged in 1794 and

the early 19th century, when the square-based

chimney in the mill yard was added, but the whole

site is now derelict. It had an external 7.5m

diameter breastshot waterwheel which was replaced by

a 10m suspension wheel, and then a turbine, plus

steam and gas engines and electricity. It became

the most extensive group of buildings in the valley.

Permission for conversion to residential use was

granted in 2016, and in 2017 it appeared to be being

cleared out, but it looked exactly the same in 2020

when we visited it again, right down to the same

pile of rubbish in the yard.

|

|

|

In contrast,

Bailey’s Mill, also known as Matlock Green

Corn Mill (below), has been converted for

residential use. Formerly Gartons & E H Bailey Ltd,

it was built for Samuel Unwin in 1799. It is also

on the Bentley Brook and had a central internal

waterwheel. The building was greatly enlarged when

a steam engine was added in the late 19th century

and roller milling was introduced at about the same

time.

|

|

|

|

It

was probably lack of competition and the relative

isolation of Bailey’s Mill which led to the

expansion of the complex in the 18th century to

include a malthouse (left). This grade 2

listed building had holes in its roof when the area

was recorded in 2010, and it was deemed to be a

building at risk. It had bigger holes in 2017 when

we saw it!

Not

in the Lumsdale Valley, but still in the

conservation area in the nearby village of Tansley,

are two more mills built by Samuel Unwin in the late

1700s. They are very similar in appearance to the

original spinning mill on the Bentley Brook, but

both have their own separate ponds. |

|

Scholes Mill (right) was built in 1797 as a

cotton-spinning mill, but was later used for

‘smallware’ – the 19th century name given to narrow

textiles such as tape and bindings made of a variety

of fabrics such as cotton, linen, silk, and wool –

rather than for spinning. It was fed by two large

ponds and like Bailey’s Mill as originally built it

had a central internal waterwheel. The building is

still in use (so I couldn’t get nearer to photograph

it) but none of its internal structures are

original, and although the brick chimney stack

remains the associated steam engine house has been

demolished.

Speedwell Mill (below) of 1783 was half the size

of Scholes Mill, and had a separate pond, an

internal waterwheel on one end of the building, and

a monumental stone arched aqueduct from the pond.

|

|

|

|

Information from the display boards provided by the

Arkwright Society,

Lumsdale Conservation Area Character Appraisal by

Derbyshire Dales District Council,

Historic England, and other sources. |

|

|

|