|

|

|

Page 3 |

Newsletter 113, Summer 2016 © Hampshire Mills

Group |

News of Mills

Longbridge Mill, Heage Windmill, Ashlett Tide Mill

Shawford

Mill

|

|

National

Mills Weekend at Longbridge

Mill

National Mills Weekend 2016 got off to a flying

start at Longbridge Mill on Saturday 14 May, despite

a bit of delay due to a loose float (board) from the

wheel found floating in the water on opening up the

wheel pit.

|

|

|

Fred Spiers and Ivor New got busy refixing the board

(left). All the young visitors, including Ivor’s

grandchildren, felt the thrill of the first throbs

in the building as the wheel turned and pounded the

water. The usual HMG milling crew of Mick, Andy,

Fred, Ivor, and Sheila all swung into action with

guided walks around the mill, handing out the bread

and tea bread to be sampled, and answering the

numerous questions. It was rewarding to see the

many adult visitors’ delight in taking home a bag or

two of freshly milled flour and a handful of recipes

(along with a note of all our milling dates for this

year plus leaflets on other Hampshire mills).

Our youngest visitor was a little lad of just three

years old who had chosen to give Longbridge Mill the

‘once over’ from the SPAB list of mills open. It

meant a long drive for his mother as they live in

Bedfordshire. Mark’s mum told us that he is a Young

Miller (the SPAB club for youngsters) and that his

favourite part of the mill is the machinery. The

next day they were travelling east to Woodbridge to

see the tide mill and the tower mill. What a lucky

little chap to have such a willing mum! (My

grandson’s favourite part used to be the taste of

the raw flour straight off the stones, which he

would lick off his hand. He is still very

interested in food! – Editor.)

Ivor and Jo New’s daughter and two grandsons spent a

lively afternoon in the mill and the boys, also

armed with bags of Longbridge flour, demanded that

their mum have a go at making loaves from the flour

they’d seen being transformed from grain.

It was interesting to learn that Jo New had worked

at Styal Mill when she and Ivor lived in Cheshire so

perhaps we can get her to ‘spill the beans’ on life

at that acclaimed mill in a future issue of HMG

Newsletter. |

|

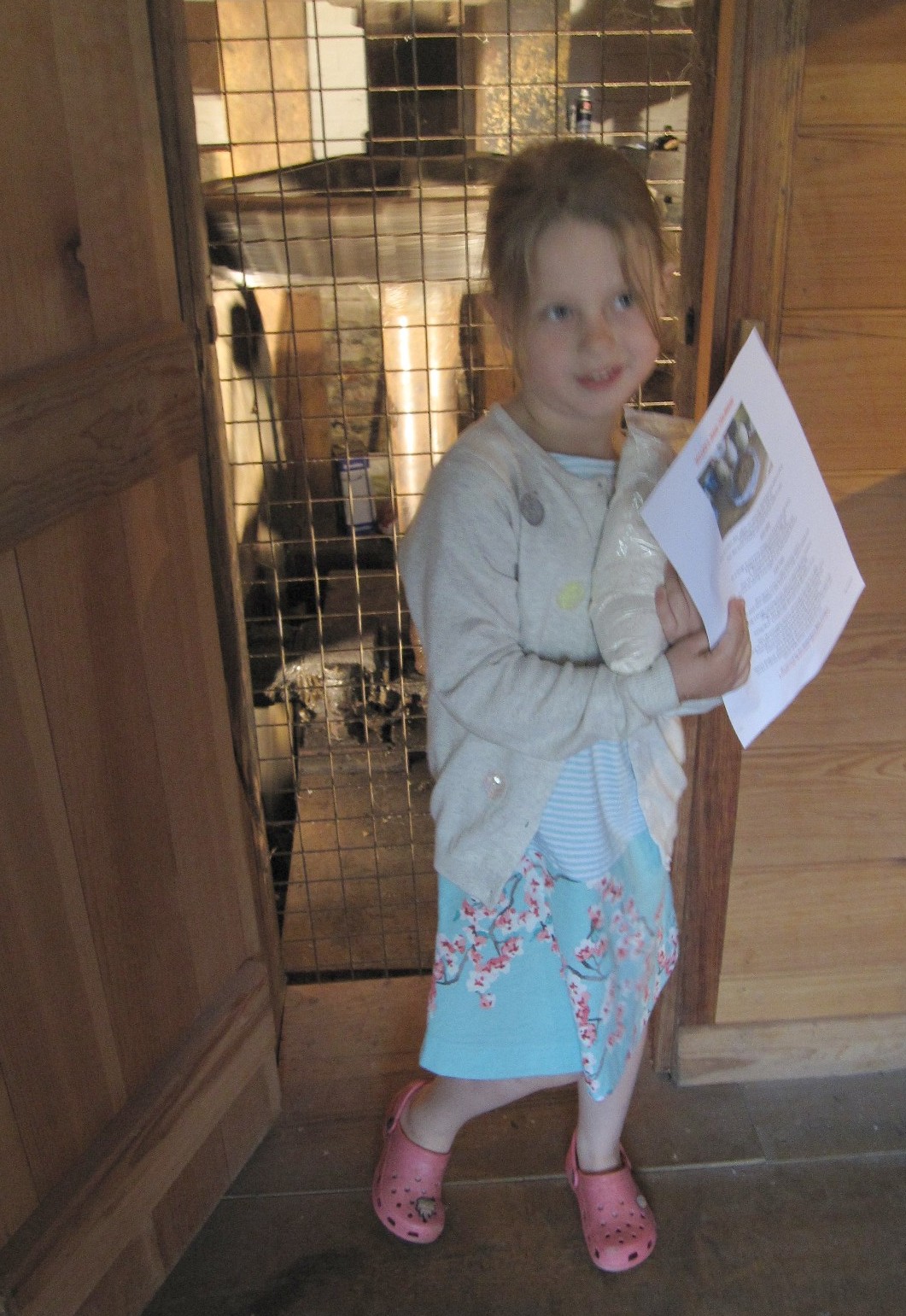

Six year old Imogen, from Basingstoke, was

enthralled with the wheel, especially when water

splashed over the walkway. Excitedly clutching a

bag of flour along with her Millers Maid Tea Bread

recipe she agreed to pose for the newsletter.

All in all a very satisfactory National Mills Open

Day at the mill.

Sheila Viner

|

|

|

Trouble at Mill

Information and photo from

http://www.heagewindmill.org.uk/

|

|

|

You may remember that in the Winter 2015 Newsletter

I wrote an article on the deterioration of Heage

Windmill in

Derbyshire. During a maintenance check it was

revealed that there was severe wet rot in the wind

shaft and the tail fan. The group have since raised

over £41,800 towards the expected total bill of in

the region of £90,000.

It was reported in January 2016 that the millwrights

were working on the major repair to the wind shaft

and the tail fan.

In the meantime, the mill volunteers were moving on

well with disassembling the shutters on the old

sails, and cutting out the dead wood on the whips.

Once this work was completed 3 coats of paint would

be needed for each of the six sails.

Ivor and Jo New’s daughter and two grandsons spent a

lively afternoon in the mill and the boys, also

armed with bags of Longbridge flour, demanded that

their mum have a go at making loaves from the flour

they’d seen being transformed from grain.

It was interesting to learn that Jo New had worked

at Styal Mill when she and Ivor lived in Cheshire so

perhaps we can get her to ‘spill the beans’ on life

at that acclaimed mill in a future issue of HMG

Newsletter. |

|

On 23 March the volunteers carried out a lot of hard

work transferring the 6 sails to a lorry, and then

unloading them back at the mill.

Towards the end of March, the millwrights lifted the

new fan tail staging into place, and at the same

time they delivered new blades and the heavy timbers

for the major front end repairs (pictured).

Unfortunately, due to the gales over Easter there

was been damage to some other mills in the area and

the millwrights had a number of other emergency

tasks to attend to before they could continue at

Heage.

During the first weekend of April there was further

progress. The stalwart gang of volunteers completed

the painting of the cap. It is gleaming white now,

and ready for the millwrights to start work on the

front end repairs.

Andy Fish

|

|

|

Ashlett Tide

Mill - an update on the retrieved millstone

You may remember reading about the millstone found

in a garden path and the saga of digging it out and

transporting it to the tide mill. That was a couple

of years ago; now, Tim Woodcock has advised us that

the millstone has been mounted on a teak plinth made

from the old sluice gate that used to control the

flow from the millpond and sits proudly on display

in the mill’s foyer. A plaque is being made to

cover the concrete-filled eye of the stone.

The 200th anniversary of Ashlett Tide Mill will be

celebrated with a weekend of family fun and music on

18 and 19 June. An excellent chance to see the

millstone so why not put the date in your diary and

join in the festivities?

Meanwhile, the great grandson of the boat builder

who occupied the mill in the early 20th century is

writing an extensive biography of his ancestor which

may be completed later this year.

Sheila Viner

|

|

Shawford

Mill refurbishment

On 3 March the Hampshire Chronicle reported that

“Shawford Mill is to be made available to rent for

£40,000 a year on a 10-year lease. It has been

restored over the last 4 years by owner Phil

Colebourn whose company Ecological Planning &

Research Ltd formerly used it as their offices. The

3-storey building is highly sustainable, principally

due to the restoration of the Gilkes-Frances turbine

which was installed in 1932. It is automatically

controlled and highly efficient, having a maximum

output of 15Kw during the winter and will provide

the occupier with extremely beneficial power rates

for electricity and for heating through a water

source heat pump system, which extracts heat from

the River Itchen.”

|

|

|

|