|

|

|

Page 8 |

Newsletter 123, WInter 2018 © Hampshire Mills Group |

|

The Black Gold of Cyprus

Ruth Andrews

Pictures by Keith and Ruth Andrews

|

|

|

|

“Until

the end of the colonial era, and before the advent

of modern agriculture with its large scale irrigated

crops like potatoes and citrus fruits, carobs were

among Cyprus’s main agricultural export products.”

Typical annual production was approximately 50,000

tons from 2 million trees. Trade was transformed in

1911 when steamships were loaded with carobs for

export to England. As a result N P Lanitis Ltd in

Limassol (Lemesos), established in 1896, became the

island’s largest exporter.

|

|

Their warehouses have now been revived as a meeting

and dining venue, and the machinery has been

retained as a museum. Keith and I came upon it when

we were trying to decide where to go for lunch. As

usual in these situations there was no leaflet to

take away, but the wall panels gave a good

explanation so we photographed them; this article

is the result. |

Dried carobs arriving from the fields, where they had been

knocked off the trees with sticks, were weighed and

size-sorted. “Foreign bodies, such as pieces of wood, or

stones, that all but accidentally had sneaked into the

farmers’ delivery bags were discarded amidst commonplace

quarrelling and practical joking.” Large pods were set

aside for export intact, but the rest were kibbled, crushed,

and sieved. There were 3 final products: small carob

cubes, carob flour, and seed.

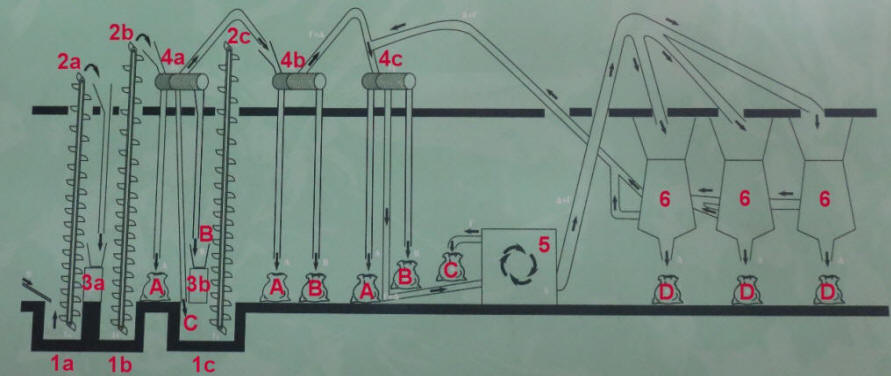

The mill machinery used in this process bears a striking

resemblance to the sort of set up that we would expect to

find in a flour roller mill at home, and was just as

difficult to photograph meaningfully. The grinding and

separation process is shown in the following flow diagram,

followed by some pictures of the machinery. I have copied

the explanatory text intact. although I have corrected and

enlarged the labels. I hope you can follow it.

|

The carobs fall into the first pit 1a where an

elevator 2a scoops them up and feeds them into the

first crusher 3a. The broken-up carobs are scooped

from a second pit 1b by another elevator 2b that

feeds them into a first cylindrical separator 4a

which produces carob meal A gathered into sacks,

medium C, and cube B. The cube is fed into the

second crusher (3b) to be crushed into smaller

pieces which are subsequently mixed in a pit 1c with

the medium.

A third elevator 2c feeds the mixture into the

second cylindrical separator 4b out of which comes

carob meal A and cube B which are gathered into

sacks, and seeds mixed with medium, which are sent

to the third cylindrical separator 4c.

This again gives carob meal A and cube B which are

gathered into sacks, and seeds mixed with medium.

These are fed into the large separator 5 where the

medium C, which is lighter, is whirled up by air to

be sent via a duct into sacks, whereas the seeds D

are fed into the final separator 6 to be completely

cleaned from any residue. From there the seeds D

are gathered into sacks, but a small quantity still

mixed with medium is taken back to the third

cylindrical separator 4c to be reprocessed.

|

|

|

|

|

|

|

|

|

These pictures from the wall display probably give a

more accurate idea of what the mill was like.

Quoting again: “The most important use of carobs

was, and still is, the enrichment of livestock

feed. For this purpose. carobs are consumed whole

or cracked (cubed) after they are kibbled, that is

after the seed is removed. The seed itself is

shelled and the embryo is separated from the

endosperm. A natural gum is extracted from the

endosperm. It is used in the food industry, in

cosmetics, in paper manufacturing, making

photographic film, and dyeing. In World War 2 it

was used in the manufacture of parachutes.”

Carob flour and syrup are used as replacements for

cocoa, coffee, and sugar, in chocolates and

biscuits. The flour has low fat content, high

natural sugar, and high levels of minerals and

vitamins. In addition to the pod, carob tree bark

and leaves contain tannin which was used for dyeing,

particularly sails.

Finally, the seeds of the carob, due to their

roughly consistent individual weight, were used –

initially in ancient Egypt – as a measure of weight

for gold. The term ‘carat’ most likely derives from

this.

|

|

|

|