|

|

|

Page 3 |

Newsletter 149 Summer 2025 © Hampshire Mills Group |

|

Meeting Report, 15 March 2025

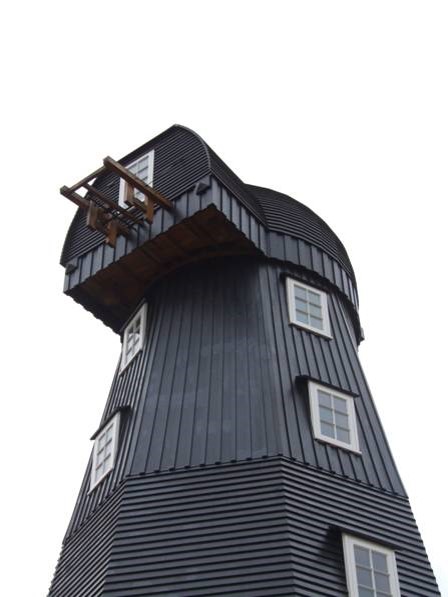

The Reconstruction of Elmer Mill, Ockley as a

Residence

Eleanor Yates, with additional notes from Peter

James

Photos by Peter James

|

|

Some 15 members of HMG came to the Spring meeting at

Warnford Village Hall, where they were able to hear

a talk about Peter James’s rebuilding of Elmer Mill.

Peter said that he had always been interested in

mills especially during holidays in the Norfolk

Broads, and later became involved in the moving and

restoration of Lowfield Windmill in Sussex.

|

|

|

|

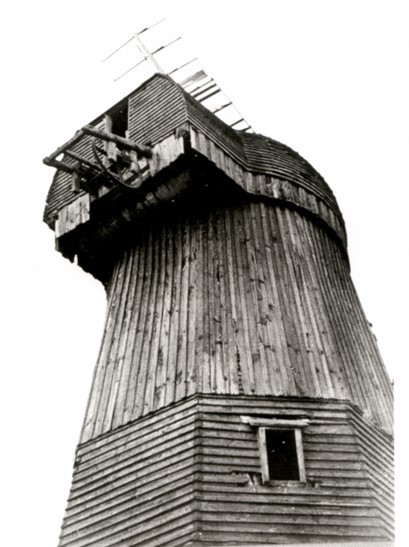

He was shown Elmer Mill, which had been an 8-sided

smock mill originally built in 1803. Photographs

from 1933 show decay in the structure of the mill

and although it was still standing in 1942, in 1944

it collapsed: either during a windy day or on a

calm day – memories vary. By 1973 it was an empty

shell with only the brick and stone base surviving.

In 2003 it was visited by Peter, who encouraged by

his then girlfriend Bridget (now his wife), bought

the ruin which is in the middle of a field.

|

|

1945: The mill collapsed in 1944

1942:

The timber wall plates had rotted on one side by

this time, making the tower a bit precarious

|

|

The project was to rebuild it as

nearly as possible to the original, to reinstate the

village landmark, to create a home, and to use local

materials and re-use materials where possible – and

to do as much of the work himself as possible.

Initial reaction to his proposal from the Planning

Department was a ‘No’, as the land was designated as

of ‘Special Landscape Interest’, which would

preclude any house building. However, they

obviously liked the idea, as they said there might

be a way – if he could get good village support. He

therefore prepared a project proposal booklet, which

he took around to 156 houses to lobby their

support; when it came to the application this

produced 100 support letters and no objections. The

plans also included the demolition of the nearby

chicken shed, thereby removing the threat of someone

putting in an application to demolish and rebuild

it.

|

|

|

|

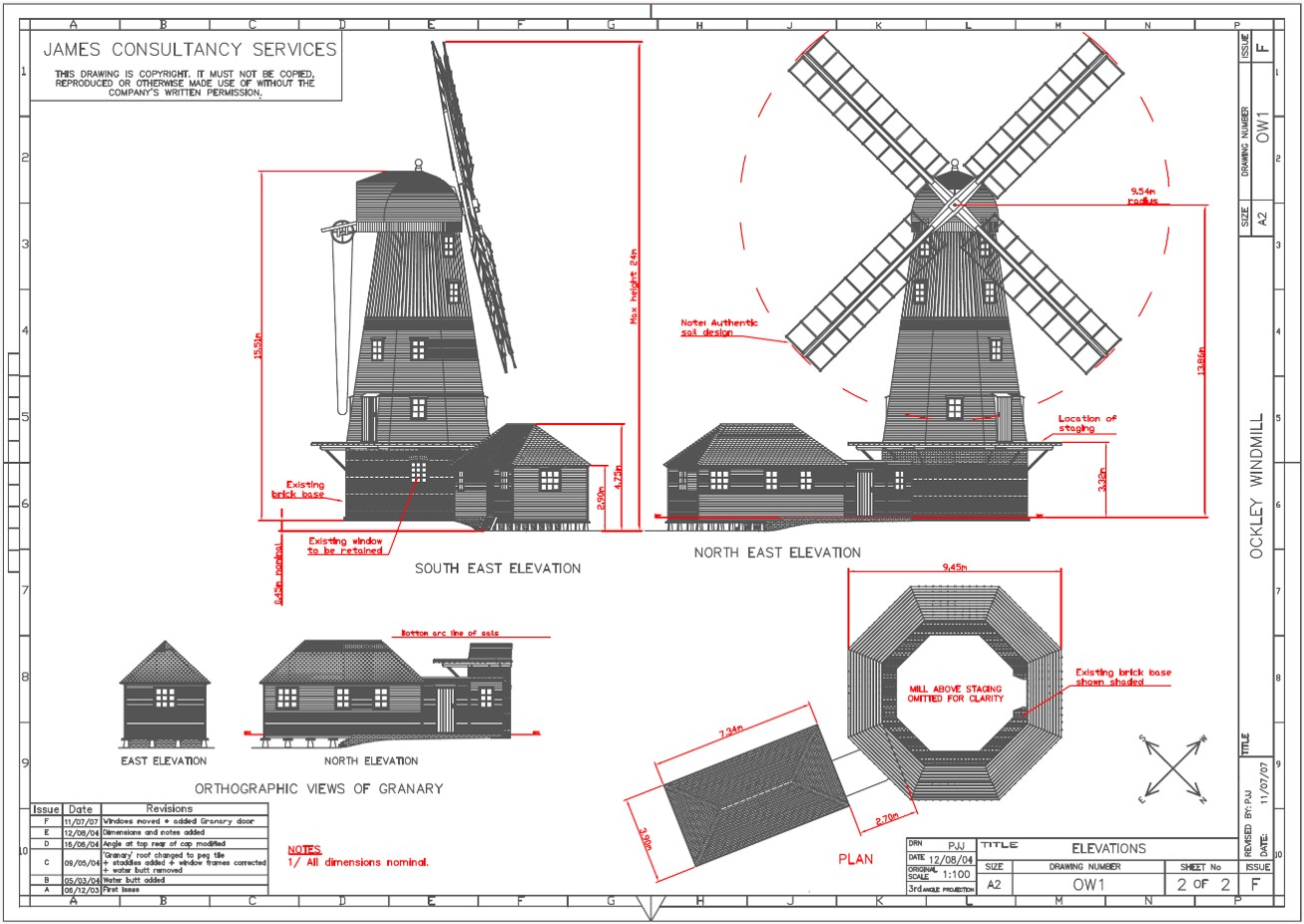

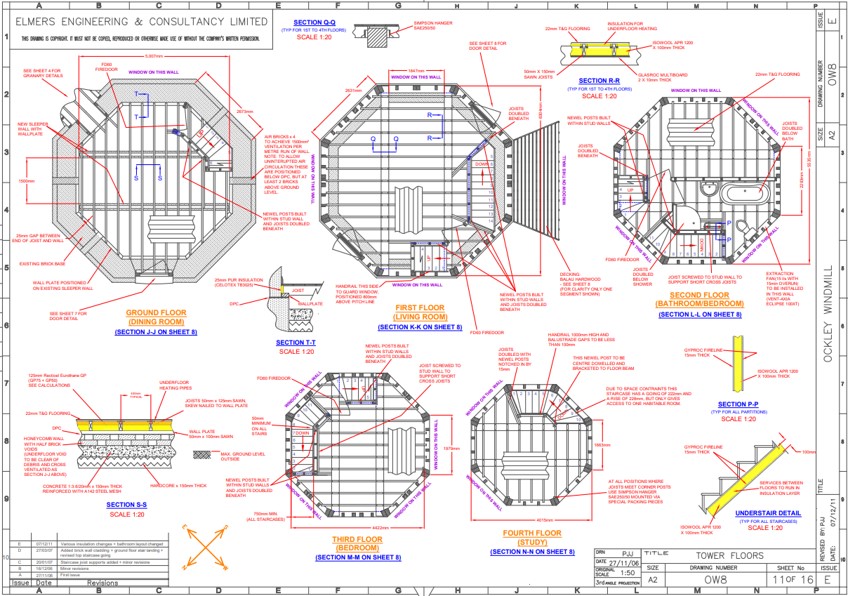

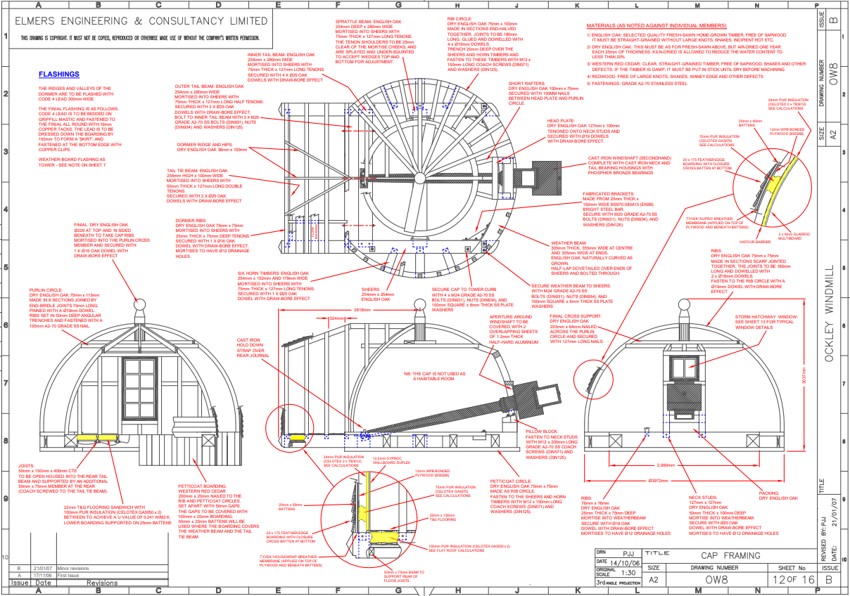

He employed a planning agent to

advise on the requirements for a planning

application. The 16 sheets of A2 drawings, to be

checked by the agent, also provided him with the

U‑value calculations for insulation, and were in

such detail that they would also be a guide to the

actual build.

Peter and a friend demolished the chicken shed with

the owner’s permission. Then CAD plans were

submitted for the rebuild – an 8-sided smock mill

with, unusually, a granary attached. Granaries are

usually separate from the mill to cut down the risk

of fire.

He obtained quotations from

millwrights like Vincent Pargeter, but although

Vincent’s drawings of the mill-cap were invaluable,

he needed to use other tradesmen. South Ockenden

Mill was a useful source of information. Peter

spent over £17,000 on timber, and staddle stones for

the granary were £65 each, but he did not tell us

how much the trenches, electricity installation, and

sewage biotank cost.

The original 230m track from the road towards the

windmill had completely disappeared beneath the

field, so he needed to reinstate it and install

services (electricity, water, …) in a trench

alongside before any work on the actual mill could

start.

|

|

The original octagonal base, despite looking in poor

condition, and with a tree growing out of it, was in

better condition than thought, with 5 good sides bar

a couple of courses. As it was important to

preserve as much of the original fabric as possible,

for both historical and aesthetic reasons, the

decision was taken to restore rather than demolish

and rebuild. One of the benefits of the brickwork

being laid with lime mortar was that the bricks

could be easily cleaned and reused.

To provide access to the new granary,

a new door was cut through, which provided

sufficient reclaimed bricks to restore the outside, thus preserving the

character. The original granary was situated

slightly south-east of the mill, but it was re-built

attached to the mill to provide a kitchen which was

impractical within the brick base of the mill.

|

|

The granary, with its staddle stones, and the brick

tower base

|

|

The oak wall plate, and curb (which fits on top of

tower).

The size difference clearly shows the taper of the

tower walls.

|

Erecting the tower

|

With the windows and door openings cut-out, the mill

is really taking shape. The tower is covered in a

breathable membrane, ready for boarding.

|

The curb in place

|

|

The construction of the cap took place initially at

the millwrights’ workshop in Burgess Hill. It was

then dismantled and transported to site, where it

was re-assembled and finished off ready for the big

lift. Back in November 2007 Peter had managed to

purchase an old windshaft, which came from South

Ockendon windmill in Essex. Note the ‘Ock’

– it must have been destined for Ockley!

This shaft was perfect to incorporate into the new

cap. |

|

|

|

Installing the windshaft

The construction of the cap

Lifting the cap onto the curb

|

|

|

There is still a lot to do if the mill is to be

fitted with sails: such as constructing the

staging, fitting a brake wheel, and making the cap

turn. The new sails won’t have a full set of

shutters, as this would present too much area to the

wind. The remains of a substantial part of the

original sails were found in the nearby pond, where

they had lain for nearly 80 years!

It seems incredible to realise now,

but it took the next 11 years to fit out the inside!

Internally Peter has added beautiful detailing in

the windows, balustrades, handrails, stained glass,

and tiling. The mill is bright and light now the

walls are plastered.

|

1933 |

2011 |

|

Luckily Peter is an engineer and skilled in CAD, and

so could do all his own technical drawings, and the

mathematical calculations for the construction of

the smock which gets narrower as it rises, the tenon

and other joints, the insulation, flashings,

battens, and the underfloor heating would have

defeated anyone else. It is tricky to accommodate

windows and staircases in a tapering structure, and

it was fascinating to hear how all of this was

achieved.

We have arranged a visit to Elmer Mill in May for

our members.

Thanks to Peter for his excellent and detailed talk,

and for lending us his notes and pictures for this

report.

|

|

|